descripción

Carbon oxide co2 compressor refers to the compressor used to pressurize and transport carbon dioxide gas. Mainly used for,

1. Recovery and storage of dry ice volatile gas in CO2 plant and recycling of waste CO2 in the plant,

2. Use the liquid characteristics of CO2 for industrial and pharmaceutical extraction process

3. Large carbon dioxide compressor is mainly used in urea synthesis unit

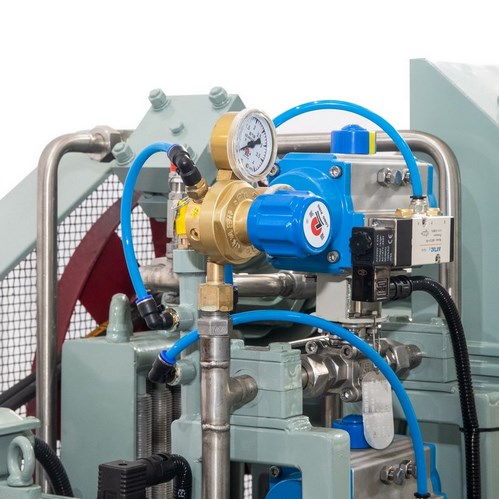

Attention should be paid during design and use: (1) the critical temperature of carbon dioxide is high, which can be liquefied at 31.3 ℃ and 7.14mpa. When used in winter, the interstage cooling temperature should not be too low; (2) When carbon dioxide is below 60MPa, it is conducive to gas compression; (3) Due to the relatively high density of carbon dioxide gas, it is not suitable to use too large average speed of piston, otherwise the resistance of gas valve is large; (4) Carbon dioxide gas contains a small amount of water and is highly corrosive, so the gas valve, cooler and buffer tank should be made of stainless steel. Carbon oxide co2 compressor refers to the compressor used to pressurize and transport carbon dioxide gas. Mainly used for,

1. Recovery and storage of dry ice volatile gas in CO2 plant and recycling of waste CO2 in the plant,

2. Use the liquid characteristics of CO2 for industrial and pharmaceutical extraction process

3. Large carbon dioxide compressor is mainly used in urea synthesis unit

Attention should be paid during design and use: (1) the critical temperature of carbon dioxide is high, which can be liquefied at 31.3 ℃ and 7.14mpa. When used in winter, the interstage cooling temperature should not be too low; (2) When carbon dioxide is below 60MPa, it is conducive to gas compression; (3) Due to the relatively high density of carbon dioxide gas, it is not suitable to use too large average speed of piston, otherwise the resistance of gas valve is large; (4) Carbon dioxide gas contains a small amount of water and is highly corrosive, so the gas valve, cooler and buffer tank should be made of stainless steel.

|

Project and parameters |

|||

|

Medium |

CO2 gas |

Quantity |

1 |

|

Inter pressure MPa(G) |

Micro positive pressure |

Inlet temperature ℃ |

0~35 |

|

Discharge pressure Mpa(G) |

2.0 |

Discharge temperature (After cooling) ℃ |

≤55 |

|

Volume flow Nm3/h |

3 |

Piston stroke mm |

55 |

|

Model |

CW-3/0.05-20 |

Compressed series |

2 |

|

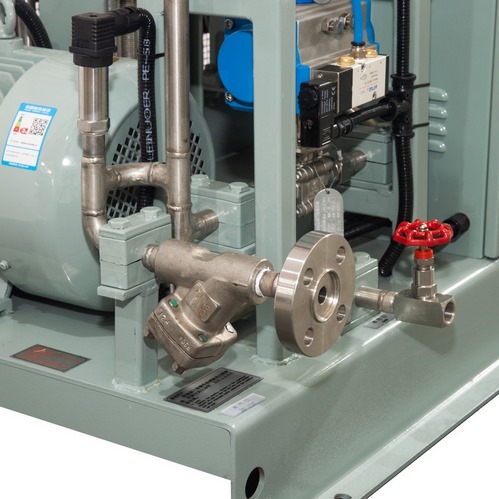

Structural type |

V type pry type |

Number of cylinders |

2 |

|

Speed of crankshaft r/min |

560 ※ |

Voltage V |

380 |

|

Cooling method |

air cooling |

cooling water flow t/h |

----- |

|

Shaft power KW |

0.8 |

Motor speed r/min |

1410 ※ |

|

Motor |

1.1kw 380V 50Hz ※ Siemens |

||

|

Outline dimension mmXmmXmm |

L700×W5550×H800 ※ |

Unit weight t |

0.48 ※ |

|

Entry / exit size mm |

DN15/DN4 |

Into / out water interface mm |

----- |

|

Driving mode |

belt drive |

||

|

Material is partly in contact with the gas

|

Body, crankshaft |

cast iron |

|

|

|

Gas valve, cylinder head |

stainless steel |

|

|

|

Piston ring, guide ring |

filled polytetrafluoroethylene |

|

|

Scope of supply |

Main engine, motor, cooler, skid-mounted chassis, start cabinet, intake filter, safety valve, random documents, etc. |

||

|

Other matters needing attention |

※Column data is for user reference |

||

|

Delivery time |

Contract signing, 40 working days after the advance payment to the account |

||

Detail Description