What are the suitable industries for helium gas compressor?

What are the suitable industries for helium gas compressor?

Helium gas compressor is suitable for the production of dye, spices, drugs, analysis, chemical condenser, a variety of fluoride and corrosion inhibitor, epoxy resin, petrochemical equipment, electrochemical plant and other chlor-alkali chemical fields. Also integrated into the hydrogen, styrene, dichloromethane, chloroethane, monochloroflorodifluoroethane and other fluoride gas reduction working conditions.

Helium is without color, melting point-114.2 degrees and melting point-85 degrees. The smell of ventricular sex, have strong stimulation to respiratory tract, presbyopia, skin, mucous membrane have erosion. The proportion exceeds the gas, and the wet and cold gas causes fog, very microsoluble strong electrolyte.

Hydrogen gas dissolves water to form hydrochloric acid. When the medicine bottle opens, it often produces hydrochloride acid and alkali mist with small raindrops in the air. Industrial grade hydrochloric acid is often yellowish yellow, the root cause is the presence of ferric trichloride.

Common sodium hydroxide to detect the presence of hydrochloric acid, sodium hydroxide and hydrogen chloride reflected into milky white ammonium chloride particles, a hydrogen chloride molecular structure is composed of a chlorine atom and a hydrogen atom. The chemical formula is HCI solution alias hydrochloric acid, scientific name hydrochloric acid. Hydrogen chloride is a gas that smells without color. Hydrogen chloride is dissolved in strong electrolytes. At 0℃, 1 volume of water can melt about 500 volumes of hydrogen chloride.

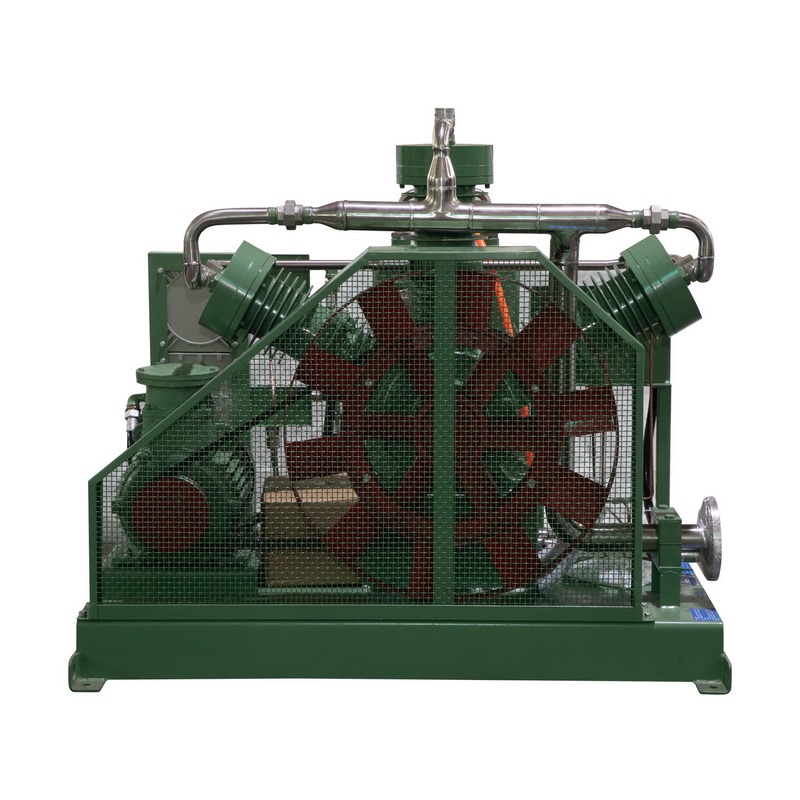

The helium compressor is a reciprocating compressor in the cylinder to reduce and transport the gas. The compressor is held by two limited plates nearby and forms the cylinder, which is driven by the hydraulic press, thus completing the reduction and transportation of the gas.

Helium gas compressor has the characteristics of large engine compression ratio, wide working pressure coverage and good airtightness. Because its air cavity does not need all moisten, and then to ensure that the purity of the gas is reduced, according to the exhaust pipe working pressure is different, generally do to become a unipolar or secondary compressor.